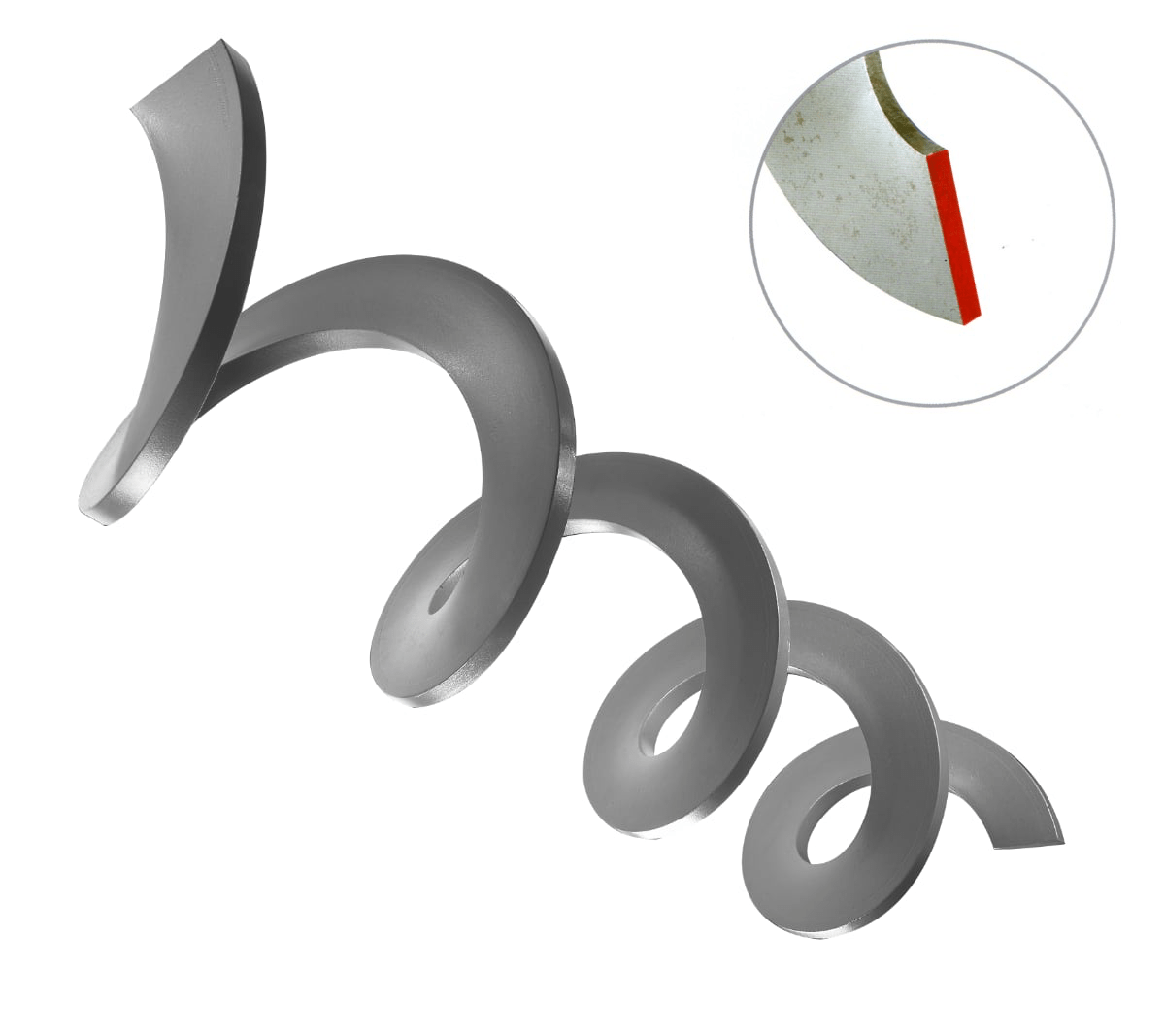

SHAFTLESS SCREW

Costruzioni Meccaniche Bertuzzo S.r.l. specializes in the production of "Shaftless Screw," characterized by a unique section reaching maximum dimensions of 150x40 millimeters and crafted with high-quality materials, which we list below.

Shaftless screw: construction materials

FE430: Structural carbon steel with a minimum tensile strength of 430 MPa.

FE510: Structural carbon steel with a minimum tensile strength of 510 MPa. Like the steel described above, this material is commonly used in construction and structural engineering applications.

AISI304: Stainless steel containing approximately 18% chromium and 8% nickel, valued for its corrosion resistance in normal environments. Widely used in food, chemical, and industrial applications.

AISI316: Stainless steel with an alloy that has higher corrosion resistance than AISI 304. Its composition includes about 16% chromium, 10% nickel, and the addition of molybdenum. Used in maritime, chemical, and pharmaceutical applications. Features

Characteristic

The main feature of a shaftless screw auger is its ability to be mounted in its conveyor without the need for central and end supports. For this reason, the conveying capacity of a shaftless auger conveyor is significantly increased, while blockage resistance is minimized. This innovative approach makes Shaftless Screws particularly suitable for handling filamentous and irregular products, as well as sticky waste materials that vary in size, volume, or moisture, along with dry solids.

Using a Shaftless Screw allows for higher filling rates and reduces revolutions per minute, contributing to lower wear and, consequently, reducing the time and resources dedicated to maintenance. This advanced technological solution is well-suited for various industrial sectors, including paper mills, sawmills, purification plants, incineration plants, wastewater treatment plants, municipal waste disposal plants, sediment separators, and waste management in slaughterhouses.

Thanks to their unique characteristics, Shaftless Screws are designed to handle a wide range of materials , including solid fuels, pulper rejects, chips, sawdust, pellets, sludge, waste, chemicals, plastic granules, powder, and more. Their versatility makes them ideal for meeting the specific needs of each customer, ensuring personalized and innovative solutions.

Bertuzzo S.r.l. continues to affirm itself as a reliable and cutting-edge partner in providing high-quality technologies, suitable for contemporary industrial challenges.

OUTER DIMENSIONS OF SPIRAL

| D | from 100 to 600 mm |

| S | da 12 a 30 mm |

D=outer diameter S=thickness